+

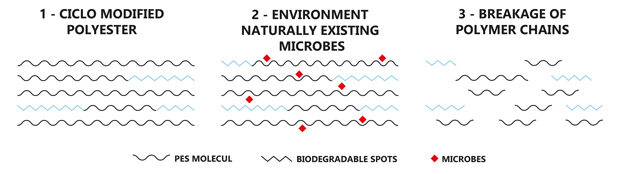

Developed with one of the latest techonology’s in the textile industry - CICLO’s modified polyester for accelerated biodegradation cycle - by embedding countless biodegradable spots throughout the matrix of polyester, the fiber is able to behave more like a natural fiber, with microbes degrading the material in a much shorter time, reducing the persistence in the environment.

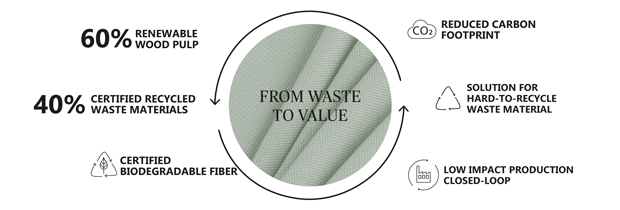

Developed to reflect the latest consumer trends towards circularity and natural-based fibers, these qualities take value from Naia Renew.

Naia renew is produced from 60% sustainably sourced wood pulp and 40% certified recycled waste material that would otherwise be destined for landfills.

Cotton is one of the most widely grown crops in the world, but also one of the most chemical-intensive, with impact on the earth’s air, water, soil, and the health of people in cotton-growing areas.

Organic cotton is a more responsible option, with organic farming practices avoiding the use of harmful chemicals while aiming for environmental sustainability and consumption of fewer resources.

The captivatingly uneven appearance of fabrics made with Piñayarn® adds a distinctive and natural appeal, exuding rustic charm while championing sustainability.

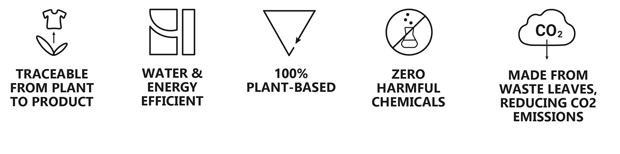

Piñayarn® works alongside nature to create quality yarns made from waste using pineapple leaf fibres offering a plant-based and biodegradable solution for textiles. Piñayarn reduces the amount of CO2 released into the atmosphere by repurposing leaves that would otherwise be burnt.

TENCEL™ LUXE is an innovative game-changing lyocell filament, derived from wood pulp that is sourced from sustainably managed forests and exclusively produced in Austria with an awarded sustainable closed-loop process. With this eco filament we create fabrics of extraordinary delicacy, soft, fluid and smooth to the touch, with a deep respect for nature in the pursuit of exceptional quality.

Fabrics produced with Renewcell’s technology allow progress towards circularity through the transformation of pre- and post-consumer textile waste, such as used pants, into cellulose pulp. - CIRCULOSE®.

This pulp can be used to produce regenerated fibers, such as viscose, and be integrated back into the regular fashion value chain.

It’s a functional finish to protect wearers from several weather conditions. Designed to accomplish sustainable values regarding its productive process.

Our FCF finish is based on a modified resin chemistry. The main purpose of this finish is to provide an alternative to the traditional water/oil repellent treatments with long-chain PFCs, for costumers looking only for water repellence and a more environmentally conscious option.

This fluorocarbon-free finishing repels water and other water-based liquids, even after multiple washing cycles. It's easy to care and ensures a longer lifetime of the garments, reducing the need of washing.

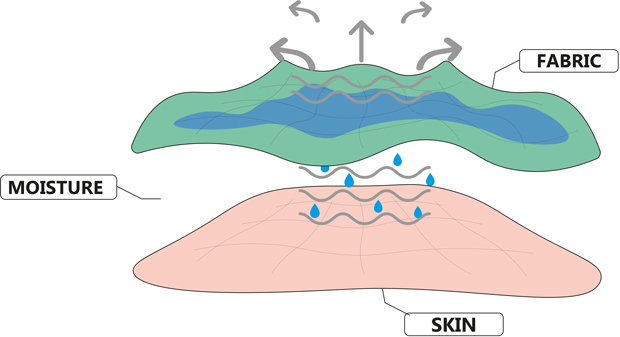

The fabric is treated with a compound that increases its hydrophilic characteristics, promoting the moisture absorption and transporting it to the outside, keeping the skin dry.

The finishing is permanent and highly resistant to washing, maintaining its hydrophilic efficiency even after multiple domestic washes.