+

At Riopele, our goal is to eliminate all hazardous chemical substances from our supply chain. Thus, our chemical management focuses on selecting safer and more sustainable products for people and the environment and reengineering production processes and product design, aiming to increase production efficiency and minimize consumption.

In addition, we respect national and European legislation, complying with the rigorous provisions of legal and statutory requirements, such as the REACH Regulation and the certification STeP – Sustainable Textile Production. We also comply with the Restricted Substance List of the ZDHC - Zero Discharge of Hazardous Chemicals - programme and are committed to the European Union’s new chemical management strategy, aligned with the European Ecological Pact (Green Deal).

Our waste management policy is based on the 4 Rs: recover, reduce, reuse and recycle.

We have installed recycling bins across our facilities to enable a selective collection of all the generated waste, preventing it from going to landfills. Our employees participate in continuous training courses and activities to raise awareness of the importance of proper waste segregation.

Our sorting system ensures the recovery of 99% of the waste we generated in 2022, contributing to the preservation of the environment and natural resources.

Our priorities are energy efficiency and reducing energy consumption. We pursue a rational and sustainable energy model and develop activities so we can become operationally carbon neutral by 2027.

We have a fully operational photovoltaic power station, with an installed capacity of 1MW, consisting of 3OOO solar panels. And in the second half of 2023, we will begin the construction of a second photovoltaic power station with an installed capacity of approximately 6MW.

In the first quarter of 2023, we started steam production at our biomass power plant, with a capacity of 65 t/d, contributing to reduce our carbon footprint, given the use of residual forest biomass.

At Riopele, we are therefore committed to reducing greenhouse gas emissions (GHG) and complying with the Paris Agreement. For this reason, we were one of the first textile companies to calculate our carbon footprint, intending to define concrete actions that can contribute with significant results for the reduction of GHG emissions.

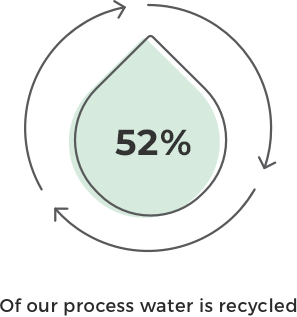

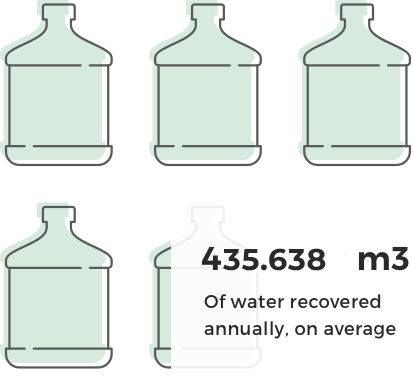

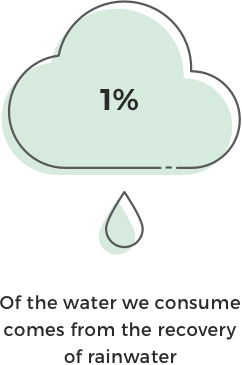

Our water management is based on three fundamental pillars: efficient management of water intake, optimization of water consumption management, and the recovery of effluents from production processes.

We are continuously investing in programmes aimed at reducing the use of water resources, reusing water and recycling industrial effluents, which allow us to achieve a level of excellence in water management and conservation.

Our facilities are equipped with a water treatment and pre-treatment plant, ensuring that all the process water is appropriately processed and routed to a proper destination while promoting its safe return to the water cycle.

Our experts regularly monitor the water quality in the river Pele, both upstream and downstream of the facilities, ensuring continuous surveillance of the river's health and ecosystem.

We seek to ensure that our processes use as few chemicals as technically possible, thus reducing the consumption of water per process and per kilogram of processed material and minimising the intensity of the end-of-line treatments.

To communicate our performance in all the aspects that support water management and conservation, as well as to promote a water-saving culture across all our levels of business, we have implemented the "Cada Gota Conta" ("Every Drop Counts") programme.

We participate in research and development projects focused on new processing technologies, seeking to find new ways of reducing the amount of water required by the various textile processes.